01.

02.

03.

04.

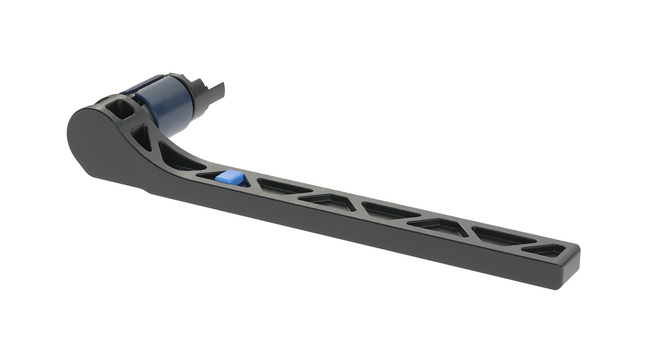

Shuttle flaps are heavy-duty components in the shuttle systems used in automated warehouses. Their function is to place items in the bays and retrieve them. When the flaps are raised, a telescopic arm reaches into the bay. The flaps then swing down behind the item and the telescopic arm is retracted, pulling the item with it.

Meeting extremely high standards of mechanical resistance and durability requires a wealth of expertise in geometry and material design. Most conventional shuttle flaps are milled metal parts which are complicated to produce. It is virtually impossible to manufacture them cost effectively in large volumes.

faigle shuttle flaps are injection moulded and made entirely of plastic. We ensure outstanding levels of mechanical resistance and durability by using an FEM-optimised ribbed construction, as well as PAS-PAA LCF, a carbon-fibre-reinforced material.

The flaps can pass hardness tests involving five million load cycles without any breakdowns. What’s more, plastic shuttle flaps weigh about 80% less than conventional steel models. The injection-moulded design allows for the integration of snap and lock functionality, which reduces the number of components.

The flaps are fitted with a maintenance-free PAS-LXY plain bearing and two shock absorbers made from soft PAS-PU.

- Lightweight design with optimised, high-strength geometry

- Outstanding durability

- Extremely cost-effective thanks to high-efficiency injection moulding

- Bearing, drive and damping functions integrated in a single component

Product information

01.

Shuttle flaps

Shuttle flaps are heavy-duty components in the shuttle systems used in automated warehouses. Their function is to place items in the bays and retrieve them. When the flaps are raised, a telescopic arm reaches into the bay. The flaps then swing down behind the item and the telescopic arm is retracted, pulling the item with it.

Meeting extremely high standards of mechanical resistance and durability requires a wealth of expertise in geometry and material design. Most conventional shuttle flaps are milled metal parts which are complicated to produce. It is virtually impossible to manufacture them cost effectively in large volumes.

faigle shuttle flaps are injection moulded and made entirely of plastic. We ensure outstanding levels of mechanical resistance and durability by using an FEM-optimised ribbed construction, as well as PAS-PAA LCF, a carbon-fibre-reinforced material.

The flaps can pass hardness tests involving five million load cycles without any breakdowns. What’s more, plastic shuttle flaps weigh about 80% less than conventional steel models. The injection-moulded design allows for the integration of snap and lock functionality, which reduces the number of components.

The flaps are fitted with a maintenance-free PAS-LXY plain bearing and two shock absorbers made from soft PAS-PU.

04.

Benefits

- Lightweight design with optimised, high-strength geometry

- Outstanding durability

- Extremely cost-effective thanks to high-efficiency injection moulding

- Bearing, drive and damping functions integrated in a single component

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.