01.

02.

03.

04.

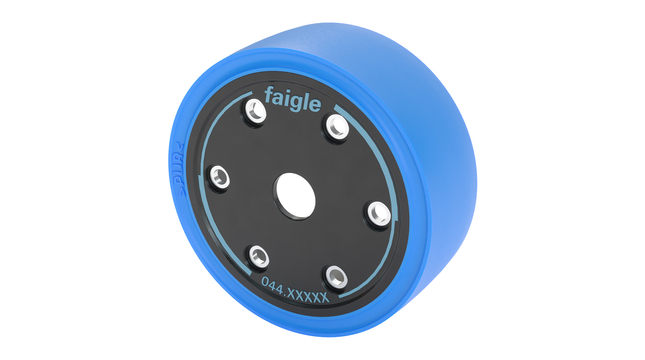

These wheels are used on automated guided vehicles (AGVs). They bear the weight of the vehicle and the conveyed goods, transmit drive power from the motor to the track, and steer the vehicle.

With only a limited installation space available (in terms of diameter and width), AGV wheels need to withstand very heavy loads and ensure excellent grip on a range of different surfaces. They also have to be extremely wear resistant, including in applications where tight cornering and on-the-spot rotation are essential. Low running resistance and low-friction cornering are important for customers for reasons of energy efficiency, especially in view of the fact that AGVs are battery-operated.

faigle’s AGV wheels usually feature a 2-component design with a polyamide hub and PAS-PU TCS tyre. A very stiff hub ensures a high load-bearing capacity.

The hub geometry is customised in line with the specifications of the drive or the transmission system. If required, faigle can use overmoulding to integrate a metal hub.

The specially developed running surface combines extremely high abrasion resistance with very low running resistance. The wheel can be adjusted to meet the specific requirements of certain surfaces by adapting the tyre material. In addition, a lightly embossed running surface ensures excellent abrasion resistance and friction-free running during sharp cornering.

All of the materials used can be supplied in antistatic or electroconductive designs.

- Low wear and running resistance for applications requiring tight cornering and on-the-spot rotation

- High load-bearing capacity, including for wheels with small diameters

- Excellent grip on the track ensures reliable drive transmission

- Injection-moulded polyamide hub allows for functional integration of connecting and drive elements

- Reliable operation with heavy loads and at high speeds, including in humid conditions

- High system availability thanks to excellent tyre bonding

Product information

01.

AGV wheels

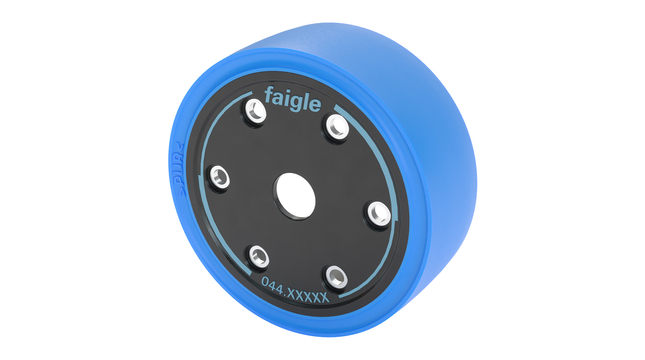

These wheels are used on automated guided vehicles (AGVs). They bear the weight of the vehicle and the conveyed goods, transmit drive power from the motor to the track, and steer the vehicle.

With only a limited installation space available (in terms of diameter and width), AGV wheels need to withstand very heavy loads and ensure excellent grip on a range of different surfaces. They also have to be extremely wear resistant, including in applications where tight cornering and on-the-spot rotation are essential. Low running resistance and low-friction cornering are important for customers for reasons of energy efficiency, especially in view of the fact that AGVs are battery-operated.

faigle’s AGV wheels usually feature a 2-component design with a polyamide hub and PAS-PU TCS tyre. A very stiff hub ensures a high load-bearing capacity.

The hub geometry is customised in line with the specifications of the drive or the transmission system. If required, faigle can use overmoulding to integrate a metal hub.

The specially developed running surface combines extremely high abrasion resistance with very low running resistance. The wheel can be adjusted to meet the specific requirements of certain surfaces by adapting the tyre material. In addition, a lightly embossed running surface ensures excellent abrasion resistance and friction-free running during sharp cornering.

All of the materials used can be supplied in antistatic or electroconductive designs.

- Low wear and running resistance for applications requiring tight cornering and on-the-spot rotation

- High load-bearing capacity, including for wheels with small diameters

- Excellent grip on the track ensures reliable drive transmission

- Injection-moulded polyamide hub allows for functional integration of connecting and drive elements

- Reliable operation with heavy loads and at high speeds, including in humid conditions

- High system availability thanks to excellent tyre bonding