01.

02.

03.

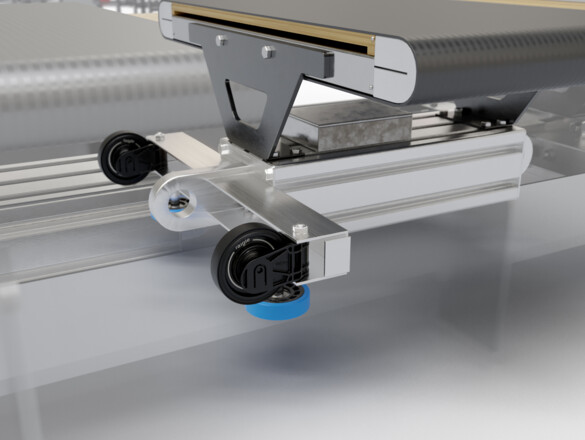

Wheel holders are part of the carriers that are used in parcel sortation and baggage handling systems. Due to the kinematic effects generated during cornering, the running wheels on the carriers need to be fitted in such a way that they can swivel. Conventional wheel holders are usually made from steel or aluminium. They have to bear the weight of the carrier and the load, while also withstanding shocks and centrifugal forces when taking corners.

Even when the wheel holders are carrying significant loads, deformation has to be kept to an absolute minimum to stop the carrier from dropping. The pivot bearings need to be play-free and silent, and to work reliably during their long service life.

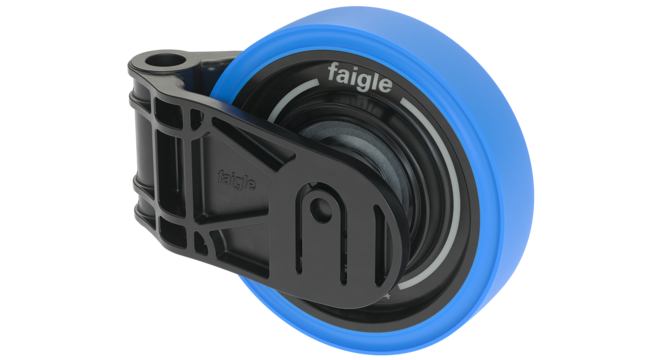

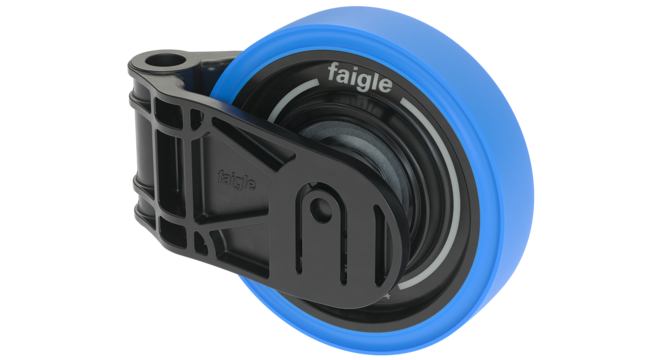

The Swivel wheel air is suitable for smaller wheels and light-weight, less heavy-duty intralogistics applications. The wheel holder comprises just three parts – two of which are standard components. As on the Swivel wheel comfort, damping bushings have been deliberately omitted, which translates into even more cost-effective assembly.

The weight of the holder is only a fraction of that of comparable steel and aluminium solutions, which helps to cut the sortation system’s drive energy requirements.

Thanks to its high-strength design featuring highly rigid, impact-resistant, carbon-fibre-reinforced polyamide, the wheel fork is ideally suited to handling heavy loads. The fork’s design is based on a platform that can be scaled according to the customer’s specific geometric requirements.

The two-part plastic wheel shaft is so stable that its load-bearing capacity is equal to that of the ball bearing. Fitted into each side of the roller, the shaft is securely attached by inserting it into the fork from the underside. This can be done by hand, with no tools required.

The material used for the wheel fork has the specific task of bearing the fork for the swivel motion. With this function in mind, the material has optimised tribological properties and does not require any lubrication during the wheel holder’s service life.

The wheel holder has an antistatic design as standard.

Ready to install, the faigle Swivel wheel air model is supplied with fully assembled running wheels.

- Lightweight design helps to cut drive energy requirements

- Cost-effective production and short lead times thanks to injection moulding technology

- Slimmed-down design delivers additional cost advantages

- Ready-to-install module reduces assembly time

- Excellent load-bearing capacity and rigidity thanks to high-performance plastics and optimised design

- Quick-change system for rapid, tool-free wheel replacement

- Fast and efficient wheel fork design suited to virtually any installation set-up thanks to flexible design platform

- Use of standard faigle parts and master mould concept translates into low investment costs and high-speed volume production

Wheel holders in parcel sortation and baggage handling systems

Application / Challenges

Wheel holders are part of the carriers that are used in parcel sortation and baggage handling systems. Due to the kinematic effects generated during cornering, the running wheels on the carriers need to be fitted in such a way that they can swivel. Conventional wheel holders are usually made from steel or aluminium. They have to bear the weight of the carrier and the load, while also withstanding shocks and centrifugal forces when taking corners.

Even when the wheel holders are carrying significant loads, deformation has to be kept to an absolute minimum to stop the carrier from dropping. The pivot bearings need to be play-free and silent, and to work reliably during their long service life.

Material

The Swivel wheel air is suitable for smaller wheels and light-weight, less heavy-duty intralogistics applications. The wheel holder comprises just three parts – two of which are standard components. As on the Swivel wheel comfort, damping bushings have been deliberately omitted, which translates into even more cost-effective assembly.

The weight of the holder is only a fraction of that of comparable steel and aluminium solutions, which helps to cut the sortation system’s drive energy requirements.

Thanks to its high-strength design featuring highly rigid, impact-resistant, carbon-fibre-reinforced polyamide, the wheel fork is ideally suited to handling heavy loads. The fork’s design is based on a platform that can be scaled according to the customer’s specific geometric requirements.

The two-part plastic wheel shaft is so stable that its load-bearing capacity is equal to that of the ball bearing. Fitted into each side of the roller, the shaft is securely attached by inserting it into the fork from the underside. This can be done by hand, with no tools required.

The material used for the wheel fork has the specific task of bearing the fork for the swivel motion. With this function in mind, the material has optimised tribological properties and does not require any lubrication during the wheel holder’s service life.

The wheel holder has an antistatic design as standard.

Ready to install, the faigle Swivel wheel air model is supplied with fully assembled running wheels.

Customer Benefits

- Lightweight design helps to cut drive energy requirements

- Cost-effective production and short lead times thanks to injection moulding technology

- Slimmed-down design delivers additional cost advantages

- Ready-to-install module reduces assembly time

- Excellent load-bearing capacity and rigidity thanks to high-performance plastics and optimised design

- Quick-change system for rapid, tool-free wheel replacement

- Fast and efficient wheel fork design suited to virtually any installation set-up thanks to flexible design platform

- Use of standard faigle parts and master mould concept translates into low investment costs and high-speed volume production

Swivel wheel air Product

Swivel wheel air – quality

Quality lies at the heart of everything we do – at faigle we are committed to ensuring that our products meet the highest quality standards. We use a series of test scenarios developed in-house to evaluate, measure and record product quality. Quality management plays an accompanying role throughout our development and production processes, in order to make sure that the results satisfy all of the requirements for the article concerned.

And we are dedicated to maximising quality for our customers, too – as reflected in our extensive range of testing equipment and approaches, as well as certification by several external organisations. It goes without saying that these quality requirements also apply to faigle’s wheel holders – robust and reliable, they meet international quality standards.

Contact

Any questions? Or do you need a personalised quote for our Swivel wheel air wheel holder?

Contact usINTRALOGISTICS

FAQs

What are the advantages of faigle wheel holders?

The kinematic effects of cornering in parcel sortation and baggage handling systems call for wheel holders that are able to swivel. Conventional wheel holders are usually made from steel or aluminium to ensure that they can bear the weight of the carriage and the load, and withstand shocks and centrifugal forces. At faigle, however, we use plastic – which is robust, but also lighter.

This is because it’s vital to keep deformation to an absolute minimum in order to stop the carrier from sinking, even when the wheel holders are carrying significant loads. The pivot bearing needs to be silent and play-free, and operate reliably over the course of many years. All of these factors mean that wheel holders need to be robust and hard-wearing, as well as quiet and long-lasting – to ensure the trouble-free operation of your sortation system.

How complex are wheel holders to install?

Installing faigle wheel holders couldn’t be easier – or quicker. We supply a ready-to-install module with the running wheel already fitted, which simplifies the entire process considerably. Robust and lightweight, the plastic wheel shaft can be fixed in the fork by means of a clip system, without the need for any tools – which makes assembly even faster. Our quick-change system means the wheels can be replaced in next to no time – a major advantage in applications with changing requirements, and when carrying out maintenance work.

The high-strength design of the wheel fork on faigle’s Swivel wheel comfort – which features highly rigid, impact-resistant, carbon-fibre-reinforced polyamide – is ideally suited to handling heavy loads, and helps to reduce assembly times as well. Alongside innovative, high-tech solutions, faigle’s new wheel holder is also extremely simple to install, which saves time and valuable resources.

Is the running wheel included?

faigle’s Swivel wheel comfort comes with a pre-fitted running wheel, which can be quickly replaced manually without the need for any tools – making for particularly speedy wheel changes. faigle always tries to see things from the customer’s perspective and their requirements are reflected in the constructions and designs of our various models. If you have any questions regarding assembly, the different forces and loads that influence your system, or any of the other products in our range, our customer support team will be happy to give you all the information you need.

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.