Longer service life thanks to smart combination of materials in attractive injection moulding process

The development of faigle’s 2C support and guiding wheel for vertical conveyors represents a major milestone in the evolution of high-performance components for intralogistics systems. Featuring a smart combination of materials that was specially developed to meet the significant demands placed on modern vertical conveyors, this next-generation wheel is a genuine alternative to conventional metal hub solutions. It stands out for its high load-bearing capacity, which translates into a longer service life and lower maintenance costs.

faigle is constantly looking to create innovative solutions that more than live up to the demanding requirements for modern-day intralogistics systems. And the company’s new 2C support and guiding wheel is a prime example. The new product was developed in collaboration with one of our customers, who was looking for an alternative to their current wheel solution that was not only fit for purpose, but also offered potential for cost savings. faigle devised a material pairing that met – and ultimately outperformed – the desired specifications.

Wheels for vertical conveyors – challenges

Vertical conveyors, which move items between different elevations, are used for storing and picking pallets, containers and boxes. Guiding wheels are a critical component in any vertical conveyor as they have a decisive role to play in the functionality and reliability of the entire system. They run on drawn steel rails and guide the load-handling attachment – which is moved vertically by a chain or belt – on the mast. Each load-handling attachment comprises between 8 and 16 guiding wheels, which need to ensure precise, smooth movement.

The wheels have to satisfy various specifications – including extremely high load-bearing capacity, in order to securely handle the load of the conveyor itself and the goods being moved, as well as abrasion resistance, mechanical stability to ensure a long service life, and high precision for smooth, vibration-free motion. Good damping properties in order to minimise noise emissions during operation, and friction-free running, which reduces the conveyor’s energy consumption, are also important.

The future of high-performance wheels

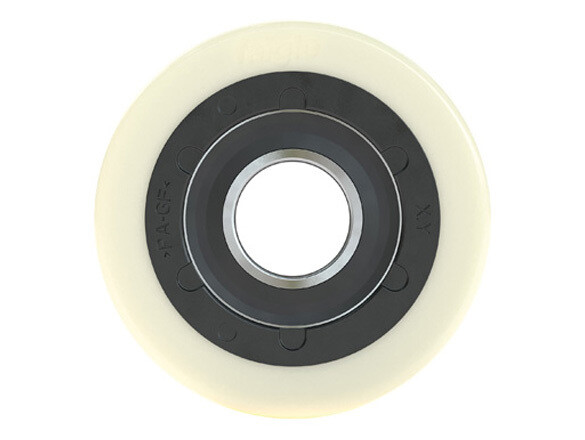

Featuring a robust combination of faigle’s PAS-PK12 material and fibre glass-reinforced polyamide, the innovative 2C support and guiding wheel is the product of a faigle-designed injection moulding solution that enhances the performance and reliability of vertical conveyors, while also significantly extending maintenance intervals.

The PAS-PK12 tyre stands out for its excellent abrasion resistance and outstanding mechanical properties. This guarantees a long service life, including for constant, heavy-duty load handling operations. The fully automated injection moulding process for the wheels delivers strong tyre bonding, and also ensures that the securely overmoulded ball bearing in the hub is permanently embedded. Besides minimising the risk of breakdowns, this also translates into high operating reliability. The smart combination of materials represents another decisive advantage by removing the need for a metal hub. This reduces the weight of each wheel by 240g, which in turn leads to lower energy consumption.

Clemens Vögel

GLOBAL KEY ACCOUNT MANAGER AT FAIGLE

Innovative, quality-approved products

A key quality assurance tool in product development and volume production, the advanced test benches used by faigle ensure that its guiding wheels meet the highest standards. The company carried out rigorous testing in consultation with one of its customers – this underlined the high-level performance and reliability of faigle’s wheels, and their superior quality compared with alternative products. Performed on an in-house test bench, checks of the maximum load-bearing capacity played a central role in the testing process. Endurance tests simulate real-life operating conditions, providing valuable insights into the wheel’s durability and wear resistance. The test results were also confirmed by the customer’s day-to-day operations.

Comparative tests against the wheels used previously revealed that faigle’s wheels are more hard-wearing when subjected to peak loads, which underscores its technological leadership in the industry.

Conclusion

Download Case Study

<iframe width="1500px" height="1190px" src="https://www.yumpu.com/en/embed/view/xHy9zVYvKqSDWmod" frameborder="0" allowfullscreen="true" allowtransparency="true"></iframe>

<div style="position:relative;overflow:hidden;height:600px;max-width:100%;" data-page-width="453" data-page-height="640"><iframe style="position:absolute;top:0;left:0;width:100%;height:100%;" src="https://www.yumpu.com/de/embed/view/VmP7E2uKGloOcnvS" frameborder="0" allowfullscreen="true" allowtransparency="true"></iframe></div>

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.