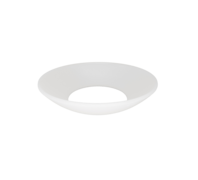

01.

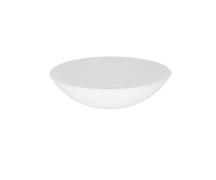

02.

03.

Centre pivot liners are fitted in the centre plates of bogies for freight wagons. Once the vehicle body has been placed on the bogie, the centre pivot liner bears its weight and that of any load, and the defined coefficient of friction ensures that the bogie runs securely on straight tracks and when cornering.

Centre pivot liners also need to withstand impact loads when starting, braking and shunting. The parts are used outdoors in temperatures ranging from -40°C to 60°C, whatever the weather.

The design of the centre pivot liner depends on the shape of the centre plate and the reciprocal part on the vehicle body. The material needs to satisfy a range of requirements: the right coefficient of friction, low wear, high mechanical strength, no stick-slip effects, self-lubricating, chemical resistance, resistance to weather conditions, and high toughness.

And PAS-60X ticks all of these boxes. It has been approved by various rail authorities, and application stretching back over 25 years underlines the material’s outstanding properties. It goes without saying that DB has also approved our centre pivot liners.

The parts are manufactured using injection moulding. The blanks are finished mechanically before going through a special heat treatment process.

- Wave goodbye to lubricants

- Rapid fitting

- Cost-effective component

- No need for lubrication brings benefits for the environment

- Significantly more expensive counter-rotating parts on the vehicle body and the bogie are protected

- Product durability depends on operating conditions, but is usually equivalent to at least one service interval (6 years)

Product information

Centre pivot liners are fitted in the centre plates of bogies for freight wagons. Once the vehicle body has been placed on the bogie, the centre pivot liner bears its weight and that of any load, and the defined coefficient of friction ensures that the bogie runs securely on straight tracks and when cornering.

Centre pivot liners also need to withstand impact loads when starting, braking and shunting. The parts are used outdoors in temperatures ranging from -40°C to 60°C, whatever the weather.

The design of the centre pivot liner depends on the shape of the centre plate and the reciprocal part on the vehicle body. The material needs to satisfy a range of requirements: the right coefficient of friction, low wear, high mechanical strength, no stick-slip effects, self-lubricating, chemical resistance, resistance to weather conditions, and high toughness.

And PAS-60X ticks all of these boxes. It has been approved by various rail authorities, and application stretching back over 25 years underlines the material’s outstanding properties. It goes without saying that DB has also approved our centre pivot liners.

The parts are manufactured using injection moulding. The blanks are finished mechanically before going through a special heat treatment process.

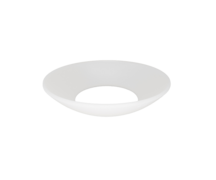

03.

Benefits

- Wave goodbye to lubricants

- Rapid fitting

- Cost-effective component

- No need for lubrication brings benefits for the environment

- Significantly more expensive counter-rotating parts on the vehicle body and the bogie are protected

- Product durability depends on operating conditions, but is usually equivalent to at least one service interval (6 years)