Plastic semi-finished products and finished parts

faigle uses materials that are synonymous with premium quality and also stand out for their cost effectiveness and excellent value for money. Tailor-made to satisfy specific customer needs, they also meet strict industry norms and certification requirements. Our experts work closely with our customers to develop bespoke solutions. Our passion for thermoplastics and our innovative mindset are the driving forces behind the continuous enhancement of our products.

Semi-finished products

Semi-finished products are high-value plastic items made using extrusion techniques. faigle’s semi-finished product range comprises around 600,000kg of articles in more than 1,200 dimensions and made from 100-plus different materials – all permanently in stock and immediately available. If you process semi-finished products, you’ll know that fast, reliable suppliers are vital. Our unique 1stCut® service (for cutting, planing, grooving, etc.) helps to rationalise your processes and take some of the load off your production department.

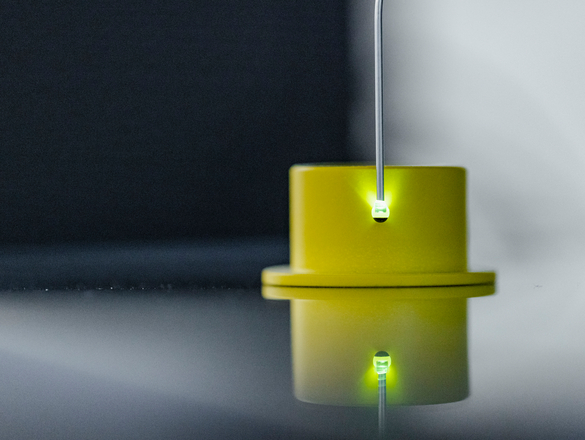

Machined finished parts

faigle has specialised in the production of machined finished parts tailored to customers’ specifications for half a century. Whether it’s complex one-off production runs or high-precision volume manufacturing, the optimised layout of finished parts ensures optimised manufacturing processes – from both a technical and a financial perspective. Our equipment is specifically configured for plastics processing and our expertise enables us to achieve unbeatable results in terms of the dimensional stability of the different types of plastic in the machining process.

Semi-finished products and finished parts – contact details

Get a personalised quote today!

Contact usSemi-finished products – downloads

All downloads

Quality from faigle

faigle is a long-standing, innovative family business. Founded in 1947, it has grown to become an international company with four locations. faigle has state-of-the-art production facilities and development centres in Europe and China. As an ISO 9001 ans ISO 14001-certified business, faigle only works with producers who have also implemented similarly high quality standards.

How can I help you?

Hi, I’m Helmut Schneller. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.

Send e-mail

Want to find out more about us?

Machined finished parts

Manufactured to custom specifications