01.

02.

03.

04.

05.

In the intralogistics sector, running wheels are mainly used in sortation and conveying systems where they have to withstand heavy loads and extremely tough operating conditions.

High availability is paramount for sortation systems because breakdowns and maintenance stoppages usually bring long logistics chains to a standstill. Running wheels need to operate reliably and without maintenance for years on end, often around the clock. Other key requirements include low noise emissions and minimal running resistance.

faigle running wheels have numerous benefits:

- Long service life thanks to hard-wearing material – significantly higher abrasion resistance compared with rubber

- No hydrolysis-related ageing or damage – reliable operation, including in humid conditions

- Attractive pricing thanks to cost-effective injection moulding

- Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years

faigle’s next-generation wheels reduce the amount of energy consumed by parcel and baggage handling systems. Optimised concentricity and running resistance means the wheels run smoothly and quietly, while the unique faigle damping system (FDS) absorbs shocks and vibrations without any negative effects on running resistance.

faigle’s next-generation wheels help to cut the energy consumption of parcel and baggage handling systems. Optimised concentricity and running resistance means the wheels run smoothly and quietly, while the unique faigle damping system (FDS) absorbs shocks and vibrations without any negative effects on running resistance.

- Long service life thanks to hard-wearing material – significantly higher abrasion resistance compared with rubber

- No hydrolysis-related ageing or damage – reliable operation, including in humid conditions

- Attractive pricing thanks to cost-effective injection moulding

- Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years

- Very smooth running

- Prevents damage to floors

- Non-marking

- Low start-up and running resistance

faigle running wheels feature a high-quality tire made from PAS-PU, a thermoplastic elastomer. The material is extremely tear-resistant, has excellent mechanical properties and is fully hydrolysis-resistant.

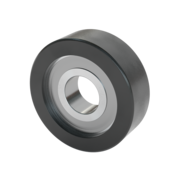

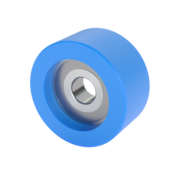

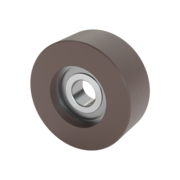

Primarily on our 1K wheels the highly pre-tensioned tire is attached directly to the ball bearing housing, while the tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. In this design, the ball bearing assembly is fully enclosed in the hub.

faigle only uses ball bearings from carefully selected, audited manufacturers

faigle running wheels deliver a wide range of benefits:

- Wear-resistant material with significantly higher abrasion resistance than rubber ensures a long service life

- Reliable operation in humid conditions thanks to resistance against hydrolysis-induced ageing and damage

- Shorter lead times and cost-effective production thanks to injection moulding

- Tightly secured tire ensures reliable operation, and the 2K wheel is also suitable for axial loads, transverse movement and cornering

Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years. faigle running wheels for sophisticated applications – quality and expertise you can count on.

The ball bearings in running wheels play a decisive role in ensuring frictionless, efficient movement. By allowing the wheel to rotate, they also enable the trouble-free movement of loads. Ball bearings reduce running resistance and make for easier handling of loads in various applications.

The differences between 1K and 2K designs underline just how versatile faigle running wheels are. On our 1K wheels, the highly pre-tensioned tire is attached directly to the bearing race. This configuration delivers precision steering and alignment of the running wheel. In contrast, the tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. Here, the bearing race is fully enclosed in the hub, which translates into added stability and durability.

Whether our 1K or 2K wheel is the right choice for you depends on the specific requirements for your application. 1K wheels are particularly well suited to situations where precise steering and alignment are vital, while the welded hub structure of the 2K wheel is the ideal choice for applications that call for stability and robustness.

This means that faigle’s extensive running wheel range can satisfy the contrasting demands of a host of different applications.

- High pre-tensioning ensures that the ball bearing race sits securely (1K wheel)

- Strong tire bonding maximises reliability (2K wheel)

- Also suitable for axial loads, transverse movement and cornering (2K wheel)

Product identification made easy – every day, we work to find the best solutions for your needs. All we need is some basic information and then we’ll get back to you as quickly as we can with a proposal based on your requirements. And whether you need wheels or other plastic parts, you can rest assured that we only use high-quality, tried-and-tested products.

Do you have any questions about our product portfolio or a bespoke product? Our experts will also be happy to give you advice and recommend products suited to your requirements.

What we need to know:

- Outer diameter (D)

- Inner diameter (d)

- Width (B)

- Quantity

- Application

- Maximum load (kg)

- Maximum speed (m/s)

Running wheels

Running wheels for every application

In the intralogistics sector, running wheels are mainly used in sortation and conveying systems where they have to withstand heavy loads and extremely tough operating conditions.

High availability is paramount for sortation systems because breakdowns and maintenance stoppages usually bring long logistics chains to a standstill. Running wheels need to operate reliably and without maintenance for years on end, often around the clock. Other key requirements include low noise emissions and minimal running resistance.

faigle running wheels have numerous benefits:

- Long service life thanks to hard-wearing material – significantly higher abrasion resistance compared with rubber

- No hydrolysis-related ageing or damage – reliable operation, including in humid conditions

- Attractive pricing thanks to cost-effective injection moulding

- Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years

faigle’s next-generation wheels reduce the amount of energy consumed by parcel and baggage handling systems. Optimised concentricity and running resistance means the wheels run smoothly and quietly, while the unique faigle damping system (FDS) absorbs shocks and vibrations without any negative effects on running resistance.

Benefits of faigle wheels

faigle’s next-generation wheels help to cut the energy consumption of parcel and baggage handling systems. Optimised concentricity and running resistance means the wheels run smoothly and quietly, while the unique faigle damping system (FDS) absorbs shocks and vibrations without any negative effects on running resistance.

- Long service life thanks to hard-wearing material – significantly higher abrasion resistance compared with rubber

- No hydrolysis-related ageing or damage – reliable operation, including in humid conditions

- Attractive pricing thanks to cost-effective injection moulding

- Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years

- Very smooth running

- Prevents damage to floors

- Non-marking

- Low start-up and running resistance

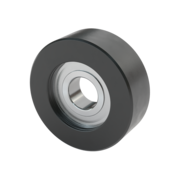

Running wheel materials

faigle running wheels feature a high-quality tire made from PAS-PU, a thermoplastic elastomer. The material is extremely tear-resistant, has excellent mechanical properties and is fully hydrolysis-resistant.

Primarily on our 1K wheels the highly pre-tensioned tire is attached directly to the ball bearing housing, while the tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. In this design, the ball bearing assembly is fully enclosed in the hub.

faigle only uses ball bearings from carefully selected, audited manufacturers

faigle running wheels deliver a wide range of benefits:

- Wear-resistant material with significantly higher abrasion resistance than rubber ensures a long service life

- Reliable operation in humid conditions thanks to resistance against hydrolysis-induced ageing and damage

- Shorter lead times and cost-effective production thanks to injection moulding

- Tightly secured tire ensures reliable operation, and the 2K wheel is also suitable for axial loads, transverse movement and cornering

Quality-controlled ball bearings that meet the highest standards ensure trouble-free operation over many years. faigle running wheels for sophisticated applications – quality and expertise you can count on.

Running wheels with ball bearings

The ball bearings in running wheels play a decisive role in ensuring frictionless, efficient movement. By allowing the wheel to rotate, they also enable the trouble-free movement of loads. Ball bearings reduce running resistance and make for easier handling of loads in various applications.

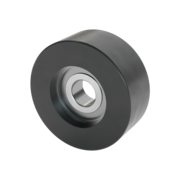

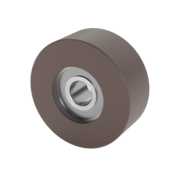

1K vs. 2K wheels

The differences between 1K and 2K designs underline just how versatile faigle running wheels are. On our 1K wheels, the highly pre-tensioned tire is attached directly to the bearing race. This configuration delivers precision steering and alignment of the running wheel. In contrast, the tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. Here, the bearing race is fully enclosed in the hub, which translates into added stability and durability.

Whether our 1K or 2K wheel is the right choice for you depends on the specific requirements for your application. 1K wheels are particularly well suited to situations where precise steering and alignment are vital, while the welded hub structure of the 2K wheel is the ideal choice for applications that call for stability and robustness.

This means that faigle’s extensive running wheel range can satisfy the contrasting demands of a host of different applications.

- High pre-tensioning ensures that the ball bearing race sits securely (1K wheel)

- Strong tire bonding maximises reliability (2K wheel)

- Also suitable for axial loads, transverse movement and cornering (2K wheel)

Running wheels – standard or custom-made?

Product identification made easy – every day, we work to find the best solutions for your needs. All we need is some basic information and then we’ll get back to you as quickly as we can with a proposal based on your requirements. And whether you need wheels or other plastic parts, you can rest assured that we only use high-quality, tried-and-tested products.

Do you have any questions about our product portfolio or a bespoke product? Our experts will also be happy to give you advice and recommend products suited to your requirements.

What we need to know:

- Outer diameter (D)

- Inner diameter (d)

- Width (B)

- Quantity

- Application

- Maximum load (kg)

- Maximum speed (m/s)

01.

02.

03.

faigle’s focus on innovative materials and advanced manufacturing technology is reflected in the outstanding quality and reliability of every single guiding wheel we produce.

We know that precision guiding and friction-free movement are crucial – and our guiding wheels are designed to meet these requirements in a variety of industries.

From the automotive industry to logistics and other heavy-duty applications, faigle helps you to find the ideal solution for your requirements from our extensive guiding wheel range.

Find out how our guiding wheels can make your motion solutions even more efficient and reliable. faigle will be happy to provide you with further details of our groundbreaking products and support your process optimisation initiatives.

- Quality and functionality you can rely on – faigle guiding wheels deliver efficient, reliable performance no matter how sophisticated your applications are.

faigle guiding wheels feature a premium-quality tire made from the thermoplastic elastomer PAS-PU. This unique, fully hydrolysis-resistant material stands out for its excellent tear resistance and top-class mechanical properties.

- Primarily on our 1K wheels, the highly pre-tensioned tire is attached directly to the ball bearing race

- The tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. In this design, the ball bearing housing is fully enclosed in the hub

- faigle sources ball bearings exclusively from carefully selected, audited manufacturers

Precision design and exact steering and alignment capabilities underline the special features that set faigle guiding wheels apart.

A securely fitted tire is especially important with guiding wheels – this ensures reliable guiding by means of special guide rails or profiles. Designed to ensure exact positioning even in highly sophisticated applications, guiding wheels make precise movements possible. Besides hard-wearing materials that extend service life, faigle guiding wheels also feature a unique design that ticks all the boxes for applications that require precise guiding.

Product identification made easy – every day, we work to find the best solutions for your needs. All we need is some basic information and then we’ll get back to you as quickly as we can with a proposal based on your requirements. And whether you need wheels or other plastic parts, you can count on us to supply high-quality, tried-and-tested products.

You can find details of our range in the intralogistics wheels section of our website. Our experts will also be happy to give you advice and recommend products suited to your requirements.

What we need to know:

- Outer diameter (D)

- Inner diameter (d)

- Width (B)

- Quantity

- Application

- Maximum load (kg)

- Maximum speed (m/s)

Guiding wheels

Guiding wheels for every application

faigle’s focus on innovative materials and advanced manufacturing technology is reflected in the outstanding quality and reliability of every single guiding wheel we produce.

We know that precision guiding and friction-free movement are crucial – and our guiding wheels are designed to meet these requirements in a variety of industries.

From the automotive industry to logistics and other heavy-duty applications, faigle helps you to find the ideal solution for your requirements from our extensive guiding wheel range.

Find out how our guiding wheels can make your motion solutions even more efficient and reliable. faigle will be happy to provide you with further details of our groundbreaking products and support your process optimisation initiatives.

- Quality and functionality you can rely on – faigle guiding wheels deliver efficient, reliable performance no matter how sophisticated your applications are.

Guiding wheel materials

faigle guiding wheels feature a premium-quality tire made from the thermoplastic elastomer PAS-PU. This unique, fully hydrolysis-resistant material stands out for its excellent tear resistance and top-class mechanical properties.

- Primarily on our 1K wheels, the highly pre-tensioned tire is attached directly to the ball bearing race

- The tire on the 2K wheel is non-detachable and welded directly onto the fibre-glass-reinforced polyamide hub. In this design, the ball bearing housing is fully enclosed in the hub

- faigle sources ball bearings exclusively from carefully selected, audited manufacturers

Precision design and exact steering and alignment capabilities underline the special features that set faigle guiding wheels apart.

A securely fitted tire is especially important with guiding wheels – this ensures reliable guiding by means of special guide rails or profiles. Designed to ensure exact positioning even in highly sophisticated applications, guiding wheels make precise movements possible. Besides hard-wearing materials that extend service life, faigle guiding wheels also feature a unique design that ticks all the boxes for applications that require precise guiding.

Guiding wheel – standard or custom-made?

Product identification made easy – every day, we work to find the best solutions for your needs. All we need is some basic information and then we’ll get back to you as quickly as we can with a proposal based on your requirements. And whether you need wheels or other plastic parts, you can count on us to supply high-quality, tried-and-tested products.

You can find details of our range in the intralogistics wheels section of our website. Our experts will also be happy to give you advice and recommend products suited to your requirements.

What we need to know:

- Outer diameter (D)

- Inner diameter (d)

- Width (B)

- Quantity

- Application

- Maximum load (kg)

- Maximum speed (m/s)

Support and guiding wheels product overview

Contact

Any questions? Or do you need a personalised quote for running or guiding wheels?

Contact usINTRALOGISTICS

Support and guiding wheels - FAQs

Where are guiding wheels used?

Guiding wheels are deployed in many different industrial applications, especially where precise guiding and steering of transported or conveyed goods is vital. The most common applications for guiding wheels are:

- Conveying and transportation systems: guiding wheels are often installed on conveyor belts and in transportation systems to ensure precise alignment and movement of goods. This is particularly important in factories, warehouses and logistics centres.

- Automation technology: when it comes to automation, guiding wheels make sure that moving machine parts are precisely aligned. This ensures reliable positioning and movement of components in automated manufacturing processes.

- Medical technology: the guiding wheels used in medical devices and applications are vital for the precise movement of instruments and samples. This is a key requirement in areas such as laboratory diagnostics and medical imaging.

Where are running wheels used?

Running wheels can be found in a wide range of applications where the focus is on moving, carrying or supporting loads. Here are some of the most common uses of these types of wheel:

- Material transport and logistics: running wheels are frequently fitted on conveyor belts, roller conveyors and other material transportation systems. They are responsible for the smooth flow of goods at production plants, warehouses and logistics centres.

- Industrial applications: many types of industrial machinery and devices feature running wheels as a means of support for moving parts. From conveying systems to mechanical engineering and production facilities, the wheels play an important part in moving loads from A to B.

- Automotive industry: in vehicle manufacturing, running wheels can be found in various applications, including conveying systems for components, and are also used to keep vehicle parts moving during the assembly process.

- Industrial trucks: running wheels are used in fork lifts, hand pallet trucks and other types of industrial truck to support and move items on the forks or platforms.

The wheels are designed to roll on smooth surfaces and carry objects in the process. In contrast to guiding wheels, which are installed specifically to achieve precise steering and alignment within guide rails, running wheels are mainly used to ensure efficient and smooth movement on flat or gently sloping surfaces.

What quality standards do faigle running wheels meet?

As a widely respected manufacturer of running wheels, faigle is committed to meeting the highest quality standards so that we can deliver products that satisfy even the most demanding requirements. Quality management is an integral part of our operations – based on strict guidelines, it ensures high product quality across the board.

At faigle, quality assurance starts with the choice of materials. Our running wheels are made from specially selected and tested materials, including the thermoplastic elastomer PAS-PU. This approach ensures that our products always meet the required performance specifications and deliver durability and reliability.

faigle’s high-precision production methods are based on state-of-the-art manufacturing technologies and processes. Comprehensive quality controls – including careful assessment of the wheels’ material integrity, dimensional accuracy and functionality – play an important part throughout the production process.

Compliance and alignment with recognised international norms and certification requirements is another mainstay of faigle’s own outstanding quality standards. The company is regularly audited and undergoes quality assessments to ensure that its wheels meet the highest industry standards.

- faigle has been EN ISO 9001 certified for a quarter of a century.

- faigle Kunststoffe also has EN ISO 14001:2015 environmental management certification.

Thanks to these comprehensive quality management measures, faigle guarantees that every running wheel which leaves the factory will satisfy your requirements in terms of performance, durability and reliability. faigle customers can also count on premium-quality products that meet our own strict quality standards. Click here to find out more about faigle’s quality management systems.

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.