01.

02.

03.

04.

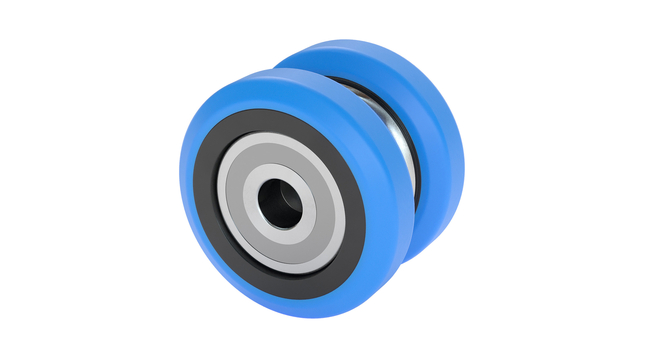

Diverter wheels are powered conveyor elements that change the direction in which goods flow in a conveying system.

The combination of relatively high speeds, the weight of the moving goods and diversion angles of up to 90° mean that the wheels are exposed to huge forces. What’s more, significant reciprocal abrasion is produced when the drive belt and the wheel come into contact.

faigle diverter wheels feature a multi-component construction, comprising a polyamide hub and two thermoplastic

polyurethane (TPU) tyres, with a metal ring serving as the liner.

We use a very stiff hub made from carbon-fibre-reinforced polyamide to enhance the wheel’s load-bearing capacity. Elastic but also robust, TPU tyres provide optimum grip and high abrasion resistance. The tyres are securely welded onto the hub and remain firmly in place despite the strong axial forces exerted on the wheel. The metal insert provides an ideal mating surface for the round belt, so it protects both the wheel and the belt against wear.

All of the materials used can be supplied with electroconductive properties, which means any electrostatic build-up is discharged.

- Secure welding between running surface and hub improves operating reliability

- Optimum coefficient of friction delivers reliable diversion

- Exceptional abrasion resistance extends service life

- Electroconductive materials eradicate electrostatic build-up

- Extremely cost-effective thanks to efficient production using injection moulding

- Simple installation thanks to delivery of assemblies including shaft and circlips

- Modular design with custom mould inserts helps to reduce mould production costs

Product information

01.

Diverter wheels

Diverter wheels are powered conveyor elements that change the direction in which goods flow in a conveying system.

The combination of relatively high speeds, the weight of the moving goods and diversion angles of up to 90° mean that the wheels are exposed to huge forces. What’s more, significant reciprocal abrasion is produced when the drive belt and the wheel come into contact.

faigle diverter wheels feature a multi-component construction, comprising a polyamide hub and two thermoplastic

polyurethane (TPU) tyres, with a metal ring serving as the liner.

We use a very stiff hub made from carbon-fibre-reinforced polyamide to enhance the wheel’s load-bearing capacity. Elastic but also robust, TPU tyres provide optimum grip and high abrasion resistance. The tyres are securely welded onto the hub and remain firmly in place despite the strong axial forces exerted on the wheel. The metal insert provides an ideal mating surface for the round belt, so it protects both the wheel and the belt against wear.

All of the materials used can be supplied with electroconductive properties, which means any electrostatic build-up is discharged.

04.

Benefits

- Secure welding between running surface and hub improves operating reliability

- Optimum coefficient of friction delivers reliable diversion

- Exceptional abrasion resistance extends service life

- Electroconductive materials eradicate electrostatic build-up

- Extremely cost-effective thanks to efficient production using injection moulding

- Simple installation thanks to delivery of assemblies including shaft and circlips

- Modular design with custom mould inserts helps to reduce mould production costs

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.