Optimising an intralogistics shuttle for TGW Logistics Group

faigle wheels for TGW Logistics

faigle and Kardex team up to optimise wheels for vertical storage system

Case study: 2K wheel for Kardex

High-performance wheels for vertical conveyors

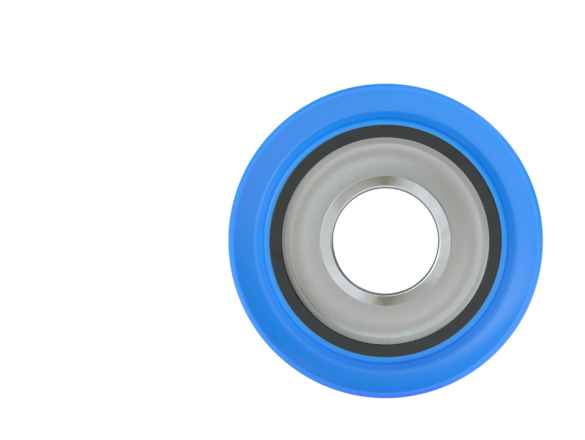

Longer service life thanks to smart combination of materials in attractive injection moulding process. The development of faigle’s 2C support and guiding wheel for vertical conveyors represents a major milestone in the evolution of high-performance components for intralogistics systems.

faigle belt guide system for curved belt conveyors

Success stories are written when ideas turn into solutions – and this is precisely the story behind faigle’s latest breakthrough. For its customer motion06, faigle developed an innovative belt guide system that not only significantly reduces assembly times thanks to tool-free fitting, but also revolutionises the entire assembly experience. Featuring fewer components and a sophisticated design, faigle’s solution delivers a combination of efficiency and user friendliness.

How can I help you?

Hi, I’m Clemens Vögel. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.